6 practical ways to use Simplebim

27.06.2024

Here at Simplebim, we talk a lot about standardising and enriching BIM data in IFCs. But what does this mean, practically, for the construction companies, architects, structural engineers, HVAC engineers, BIM managers and quantity surveyors who use our data-wrangling software? And how do they benefit? What follows are six practical use cases direct from the people who use it most, our customers.

1. Map data at a granular level

The UK’s Hinkley Point C nuclear power station project has one of the highest surveillance and quality-controlled environments in a major civils project anywhere in the world. The ability to model and transfer data at a granular level is vital for forecasting, budgeting and resource planning.

With Simplebim, Bylor’s digital engineering team have been able to manage the build properties to the finest detail. With 50 million individual reinforcement bars set in 30,000 individual concrete pours, the team can manage and track each single bar and each concrete pour.

“All of a sudden, by using Simplebim we were able to clearly quantify what data is associated with every single concrete pour. It sounds basic but it’s fundamental, not just for understanding what is in each pour, but as a contractor, being able to map data from one source of design to another source of design is, is an incredible asset.”

Terry Parkinson, Senior Digital Engineer, Bylor

2. Automate bill of quantities (BQ) with minimal requirements

Thanks to the Simplebim ‘Translator UI’, ZECH Bau’s team can standardize the alphanumeric data from multiple sources without setting any alphanumeric data requirements.

Only the geometry has minimal requirements but in terms of alphanumeric data, they can work with any 3D models, no matter what the quality.

Not only does this reduce pressure on suppliers to meet specific data requirements, but the automated standardization of the data also saves time for the cost estimators and increases its accuracy too.

“Thanks to the Simplebim ‘Translator UI’, our team can standardize the alphanumeric data from multiple sources without setting any alphanumeric data requirements. Not only does this reduce pressure on suppliers to meet specific data requirements, but the automated standardisation of the data also saves time for the cost estimators and increases its accuracy too.”

Bryce Ramsay, Cost Estimator, ZECH Bau

3. Create IFC models with data that is relevant to multiple disciplines

A key challenge for French BIM consultants BIMSKY, when working on a domestic housing estate project, was that the 3D models created by architects were not showing the relevant information for quantity surveyors, so they had to modify the properties/attributes and their values manually.

The team were able to use Simplebim to correct and optimise the IFCs for a quantity surveyor’s requirements. They then used templates to insert the lists of elements into the architectural model.

In addition, Simplebim allowed them to automate some functions in order to process quick updates.

“Thanks to Simplebim, we have been able to set up a collaborative approach between the architects and quantity surveyors, particularly with regards to updating digital models.”

Pascal Boulée, BIM Manager, BIMSKY

4. Make BIM models easier to read

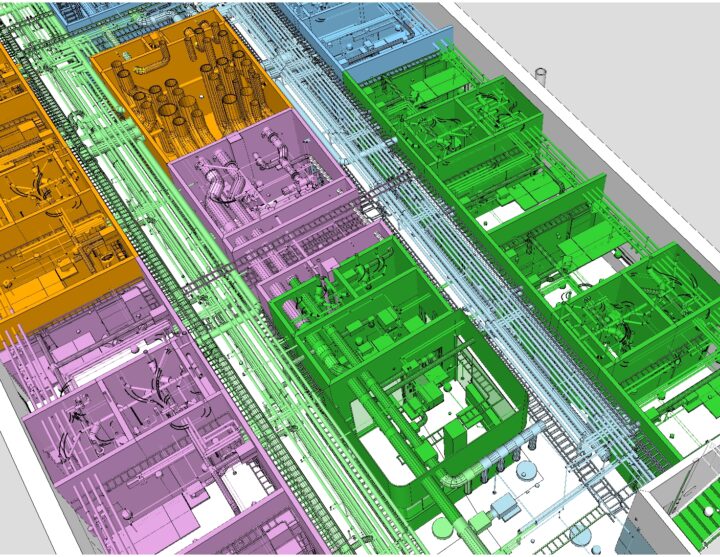

Reading grey and white BIM models can be difficult, especially for site workers viewing them on small devices such as a tablet.

Swedish construction company Byggstyrning solved this problem by using Simplebim’s ‘Colorize’ feature. Colorize allowed them to add colour to specific elements so they can be easily identified. This has been particularly useful for MEP (mechanical, electrical and plumbing) installations.

“The color-coding feature is one of my favourite features. Before we used Simplebim for example, all the elements were grey or white. So, all the mechanical, electrical and plumbing installations didn’t stand out.

Now we can colour code each discipline e.g., plumbing is brown, so you can instantly differentiate between them. We can even colour code the hot and cold-water pipes so you can see which is which.”u

Johannes Ris, CTO, Byggstyrning

5. Easily remove unwanted data from IFCs

With data coming in from multiple sources, often of varying quality, it can be impossible to separate the useful data from the unwanted data.

French construction company GCC Groupe used Simplebim to remove this data quickly and easily, lightening the models and making them easier to work with.

“Despite the multiple sources and varied quality of the IFCs received from our stakeholders, the process of importing and editing the models has been made easier and less time-consuming with Simplebim. The team has been able to check each model and remove unnecessary data to lighten the models. Simplebim has also allowed us to standardise the data across all the IFCs, opening up new possibilities for using the models.”

Thomas Crouan, Head of BIM Service, GCC Groupe

6. Automate design updates

The capability of the Simplebim engine to support automation of standardisation of IFC models has been hugely beneficial to Nordic construction company NCC in saving time and resource.

With over 120 projects running concurrently across Norway, Denmark, Sweden, and Finland, NCC is able to use Simplebim to standardise the data for each of these projects each night.

This automation saves approximately three to five hours, per week, per project, which amounts to at least 300 working hours per week across the business, freeing up specialists to carry out other valuable work.

“We get regular, at least weekly, updates from designers on IFC models. Usually, you would need to have a BIM specialist to go through each file manually to standardise the data. Now, using Simplebim, the process is automated. We do not need that number of specialists in the project, and we only have to act if there is something wrong in the automation process.”

Marcus Bergljung, Senior VDC Method Developer, NCC

***

Interested in trying Simplebim for yourself? Contact our expert team or book yourself a free, 15-day trial.