Quantities by Location from the IFC Model – Jorvi Hospital, HUS

26.06.2025

“At the construction site, the electrical contractor continuously uses model-based quantities by takt area to manage material deliveries. This ensures that the correct amount is ordered and prevents excess materials from piling up unnecessarily.”

Juho Kuokkanen, Quattroservices Oy, Jorvi Hospital construction site.

The main contractor for this HUS Helsinki University Hospital project in Espoo is SRV, a global leader in the advanced use of building information modeling (BIM). For the Jorvi Hospital project, SRV is using a standardized and automated BIM data enrichment process built on Simplebim software.

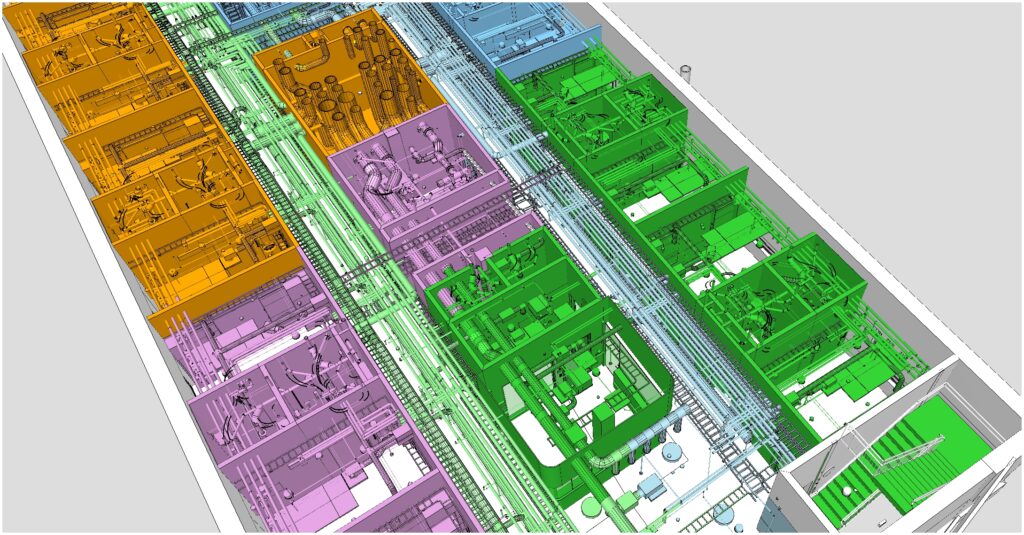

As an important part of this BIM data wrangling, all BIM models are automatically enriched with location data. Depending on the model’s size, processing takes from a few minutes up to twenty minutes and is regularly applied to every new version of the IFC models. The enriched models are saved automatically in a designated project folder. This ensures that the location-based quantity data used on site remains consistently up to date.

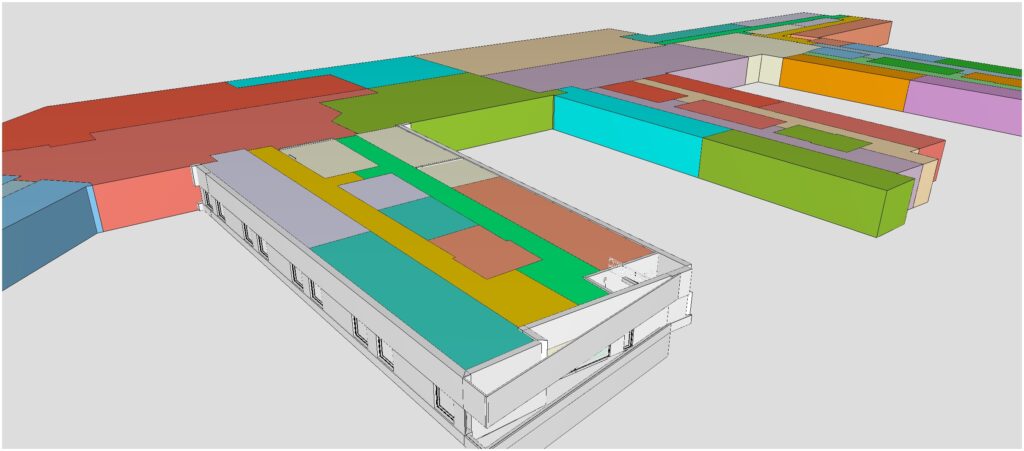

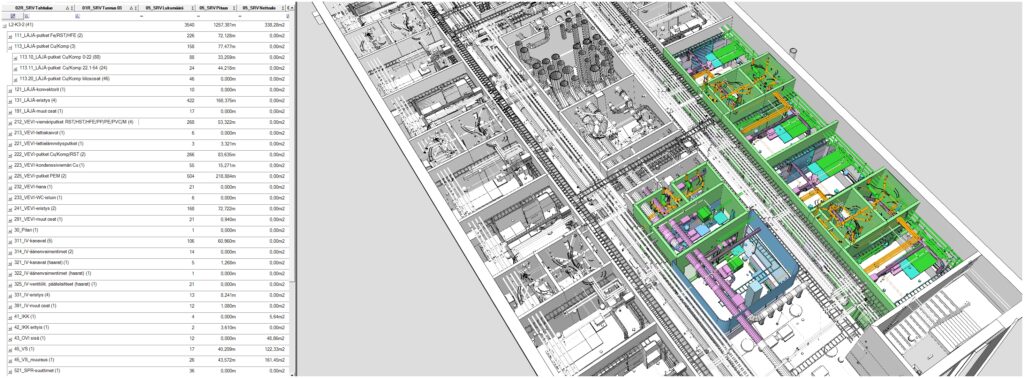

Jorvi Hospital’s plans consist of nearly 30 IFC models in total. The benefit of the automated location processing and quantity generation using Simplebim is significant, especially since takt production is used on site. The building is divided into over 200 takt areas, according to which the quantities are calculated.

How Location Enrichment Works in Practice

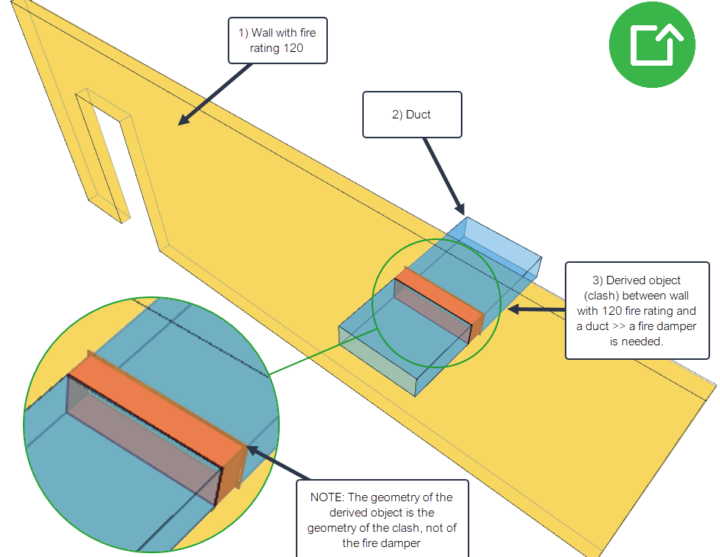

Simplebim offers two main tools for enriching model objects with location data: location prisms and the proximity tool. In the Jorvi Hospital project, locations were implemented using prisms.

Location prisms are 3D objects that contain one or more location attributes, such as section or takt area data, to be assigned to the parts within the prism. These prisms can also cut objects that cross their boundaries or fall within multiple prism areas. Simplebim automatically recalculates quantities for all objects based on their geometry—this means that also cut objects are assigned quantities based on their new geometry.

A location prism can be an existing object in the model or a separate IFC file that contains only the modeled 3D location objects. The same location prism file can be applied to all project models and reused for every revision throughout the project. If the design changes, the location prisms can simply be updated. Processed models also make it easy to spot incorrect location assignments visually.

“There were a few times when materials from the next takt area ended up in the order—so the takt data wasn’t always fully aligned with the latest layout changes. But despite that, the location data has been very useful, and I hope we’ll have it available in future projects too,”

Juho Kuokkanen, Quattroservices Oy, Jorvi Hospital construction site.

Location-based quantities support a variety of use cases

Throughout the project lifecycle, there’s a strong demand for various types of location-based quantity lists, since most use cases are quantity-related. The model should be easily split into suitable parts based on the user’s role or task. Location-based quantity requirements for cost estimation or permit process differ greatly from those of takt production, which again differ from needs during maintenance.

As the project progresses, one party might want quantities by floor, another by section or pour area, and yet another by apartment, room, or cleaning and tenant areas. With Simplebim, a single model can be enriched with multiple overlapping location prisms, enabling the same IFC model to serve many different use cases. Here is one example.

“Our team assisted in verifying the final financial report for the drywall subcontractor in the Jorvi Hospital project. We enriched the latest architectural model with sections and extracted quantities of drywall elements by location. These were compared with the quantities reported by the contractor. It was great to see that the results matched.”

Heini Kiviranta, BIM team leader, SRV Oy.

Always in a Hurry

In most cases, quantities are needed right away. Ideally, they should be directly extractable from the model by location. However, it’s not realistic to expect designers to assign and maintain detailed location data for every object. The person using the data is often the best expert to define, name, and update location boundaries.

This is where Simplebim shines: anyone can enrich a model with the location data they need using the desktop version. The workflow is quick and simple with the dataflow tool—just open the IFC model, import or select the location prisms, enrich the model, and export the enriched IFC.

When the number of models and processing tasks grows, it’s best to switch to Simplebim Cloud automation, as was done in the Jorvi Hospital project. In this setup, enrichment is performed automatically using rule sets and scripts—without need to open models. It’s a fast, scalable solution for handling large volumes of data processing.

Think Big

SRV has become a leader in scaling the use of BIM data wrangling environments. Processing IFC models has become routine across the company’s projects. In practice, almost all projects are run through a processing pipeline where every IFC model and revision is enriched using Simplebim Cloud automation. In total, around 100 projects go through this process each year. That’s nearly one thousand processed IFC models every month.

Beyond location enrichment, the IFC models undergo several additional enrichments with the aim of making model-based quantity use easy and consistent across projects and teams. The goal is to create a standardized experience from project to project—regardless of the designer or the original modeling software.

For example, data fields in IFC models are automatically standardized, ensuring object data is always stored in the same structure. Another example is enriching models with production-based groupings, making quantity takeoffs and analysis far more accessible than working directly with original IFC models, which can often feel like detective work.

“After using IFC standardization and enrichment for over 10 years now there is no way back to using original IFC files in projects.”

Heini Kiviranta, BIM team leader, SRV Oy.

All enrichments in Simplebim Cloud data wrangling process are rule-based and therefore flexible – automatically adapting as designs evolve. Enriched data is written directly into the IFC file, so it stays with the model and can be used in any compatible software.

As we like to say at Datacubist: When models are enriched and standardized with Simplebim, every other tool performs even better.

About the author

Maria Lennox is Head of BIM Data Product Development at Datacubist and a long-time pioneer in BIM data management.

An architect by training, Maria brings over 30 years of experience in the construction industry and has worked with major Nordic companies. At Datacubist, she focuses on developing scalable data products and workflows that make IFC data more structured, consistent, and usable across all phases of a building’s lifecycle.