How I use Simplebim: Byggstyrning’s CTO on using Simplebim as a key part of its digital construction workflow

With innovation and industry development at the heart of the business, Swedish construction company Byggstyrning’s fully digital approach is key to its success. From planning to production, the organisation’s digital construction workflow uses innovative technology to deliver better results for its clients.

For CTO Johannes Ris, who has been using Simplebim for almost five years, adopting the tool was an “easy sell” to the senior team.

Responsible for VDC (Virtual Design & Construction) at Byggstyrning, he described Simplebim as “a great toolbox of everything I need to create a smoother digital workflow”.

Ris spoke to us about how he uses Simplebim and how it has benefitted his organisation throughout the project lifecycle.

What challenges were you facing before you adopted Simplebim?

Johannes Ris: We had a lot of problems with the quality of the 3D models coming from the different stakeholders and different disciplines on the project. It’s our job to coordinate all these elements and manage the design work.

Before Simplebim we had to undertake huge manual processes to quality check all the models and make sure all the data was correct.

Because there is so much data involved it was hard for us to manage, and even though we had routines and set guidelines that everybody should follow, we still had problems with people delivering the wrong information in the models.

Were there any other challenges?

JR: The other major challenge was when we handed the models over to the contractors on site.

We wanted to put together all the data sets from the designers of each discipline, so we would have one 3D model to hand over to the contractor.

To do this we needed to have some kind of tool where we could add each layer of data into one 3D model.

So, how are you using Simplebim?

JR: When you are working on a construction project, changes happen regularly so the designers export updated models to us on a weekly basis.

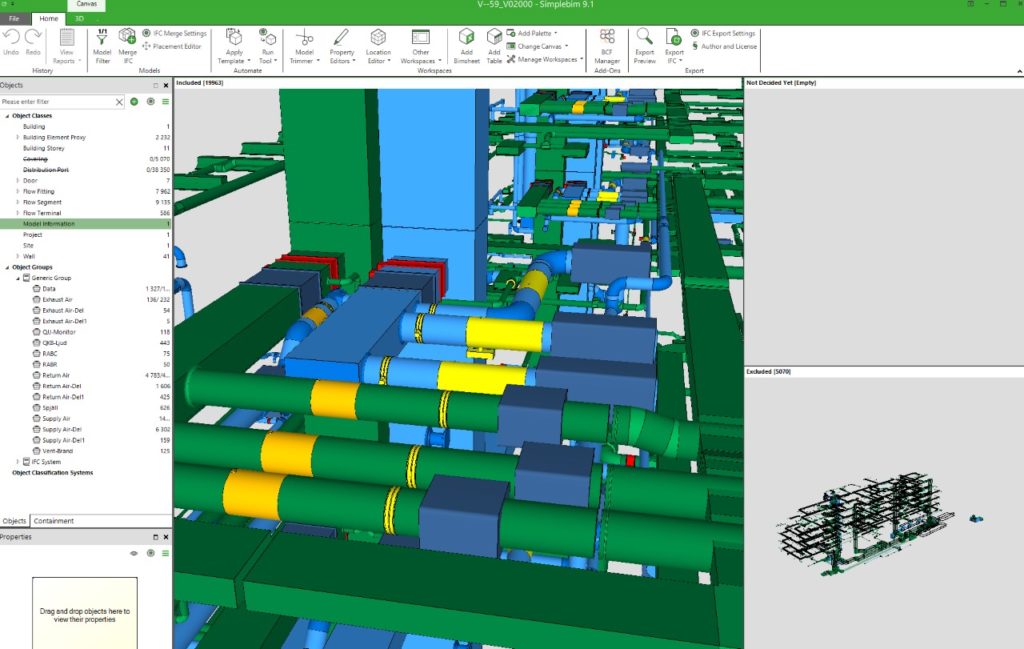

Once the models have been exported to our servers, we have a scheduled routine where Simplebim automatically carries out specific tasks e.g., cleaning, colour-coding, splitting or merging the models until they are ready to use.

The models are then transferred to our mobile platform for viewing, so we have a fully automated way of updating our mobile applications.

How much time have you saved by using Simplebim?

JR: In one typical project we have at least five people, including an architect and a construction engineer, who need to do exports and make sure all the data in those models is correct.

Then I also have to quality check everything and move the files to the correct location. All this would usually take at least 10 hours, per project, per week.

We currently have four live projects, so Simplebim is saving us approximately 40 hours per week.

How does Simplebim help you to manage the data in the 3D models?

JR: Simplebim allows us to create groups for different product categories e.g., all the wooden doors are in one group, all the steel doors are in one group. This means we can easily access the different groups.

With Simplebim we can also colour code each category with different colours.

We can also automatically put together information from different places into one single place, or “property set” as it’s called in Simplebim, so we can group information into one place as well so we can easily access it.

Using Simplebim we’re able to split models too, for instance where the model is too big to load into the mobile application.

How does this improve your day-to-day work?

JR: Before using Simplebim, we spent a lot of time working with the designers to perfect the model exports so we could deliver the quality of 3D models that we needed for our site workers.

Now the designers can focus on the work they actually enjoy i.e., designing, and we can get consistent, high-quality models more quickly and easily.

It’s great to be able to trust the 3D models that we deliver and to be completely in control of the quality. When we hand them over to contractors, they can start using the 3D models in their structural work and we can be confident that the information in the models is correct.

How do the 3D models help the site workers?

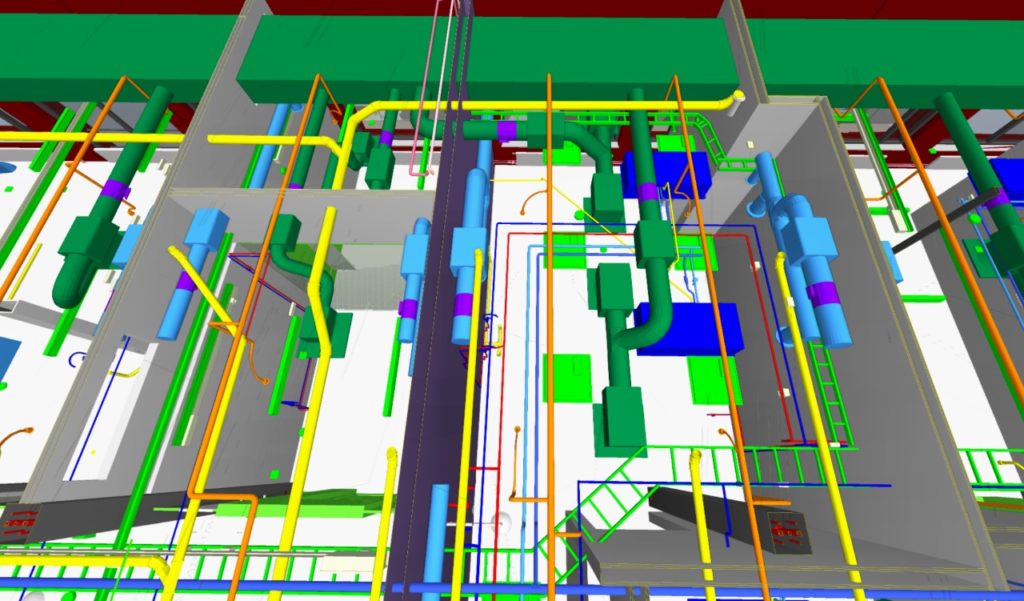

JR: The models give them a better understanding of what they’re building because they can actually visualise it in 3D e.g., if they are building walls, they can see what type of walls, the material, the dimensions etc.

The models can also be filtered based on the discipline so they can focus on the information that is relevant to them.

What are your favourite Simplebim features?

JR: My favourite feature has to be the automation, as it saves so much time and effort.

Also high on the list is the colour-coding feature. Before we used Simplebim for example, all the elements were grey or white. So, all the mechanical, electrical and plumbing installations didn’t stand out.

Now we can colour code each discipline e.g., plumbing is brown, so you can instantly differentiate between them. We can even colour code the hot and cold-water pipes so you can see which is which.

How easy was it to get started with Simplebim?

JR: It was really easy. Once I’d installed it, it only took a few minutes to get going. It’s really intuitive and I really liked the graphics.

Also, the documentation on the Simplebim website is brilliant.

And on the few occasions where I’ve needed support from the team at Datacubist, they’ve responded almost instantly. The customer service is great.

Would you say that Simplebim gives you a competitive advantage when bidding for work?

JR: Byggstyrning is a fully digital business and the digital construction workflow we have developed, including quality of information, and time and cost savings, gives us a competitive advantage. Simplebim is a key part of that workflow.

There have been projects where a client has come to us having seen our way of working and the results we’ve delivered for other clients, then asked us to do the same for them.

Why not give your organisation a competitive advantage and offer your clients the quality, and time and cost savings that Simplebim can facilitate? Get in touch with the helpful and responsive team at Simplebim and book a demo.